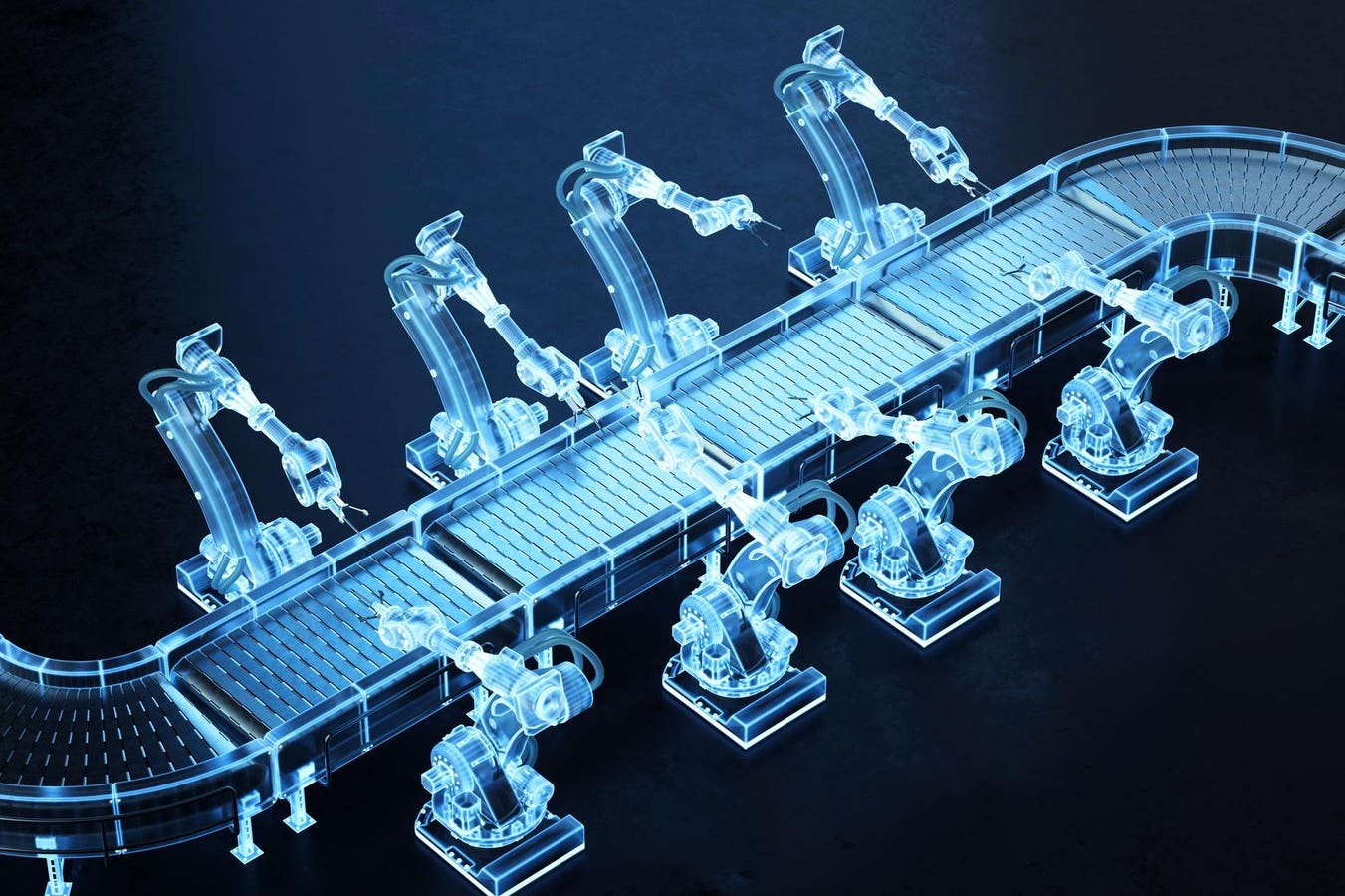

Richard Lebovitz, founder of LeanDNA, emphasizes the transformative role of AI in optimizing supply chain performance. Traditional digital twins served primarily as reflective models, lacking the ability to execute or respond effectively during disruptions, such as in manufacturing when critical components are short. With advancements in AI, digital twins are evolving into intelligent systems capable of optimizing, executing, and learning continuously. This “optimized execution” entails three phases: strategic optimization of inventory policies, intelligent execution through prioritized action recommendations, and continuous learning from operational data. The integrated architecture of these systems ensures real-time data synchronization, prescriptive analytics, and a feedback loop for improving execution accuracy. While there are challenges in data quality and implementation, organizations that adopt AI-driven solutions can significantly enhance efficiency—reporting reductions in excess inventory and improvements in delivery times. As supply chains increasingly face disruptions, adopting intelligent systems becomes essential for maintaining competitive advantages.

Source link

Share

Read more